The Role of Bioreactors in Scaling Lab-Grown Meat Production: Innovations and Challenges

The Role of Bioreactors in Scaling Lab-Grown Meat Production: Innovations and Challenges

Lab-grown meat provides a revolutionary solution to food sustainability challenges. As the global population grows, traditional livestock farming struggles to meet demand. This situation increases the need for alternative protein sources. Bioreactors facilitate lab-grown meat production by cultivating animal cells into muscle tissue. However, innovations and challenges impact this technology’s contribution to a sustainable food system.

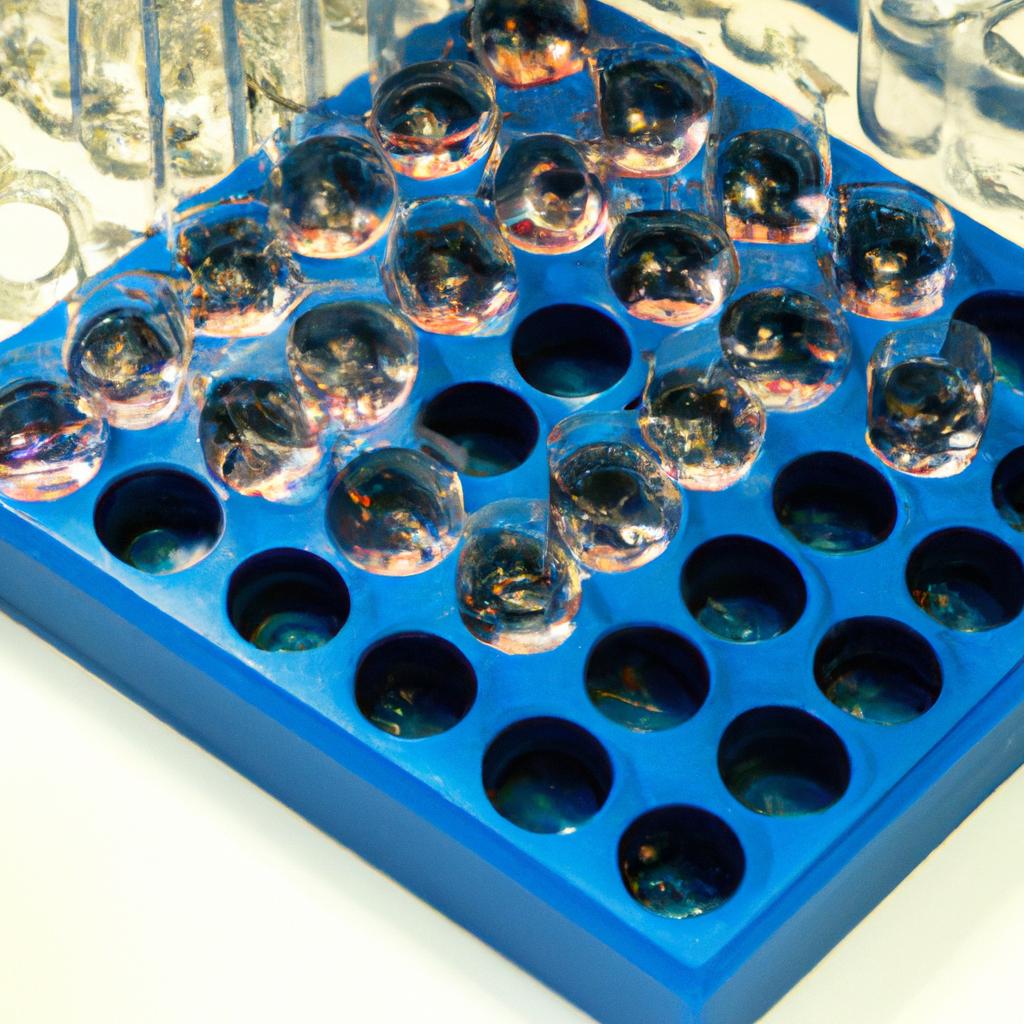

What Are Bioreactors?

Bioreactors are vessels that facilitate biological reactions for lab-grown meat. They house animal cells in controlled environments. These systems supply necessary nutrients and maintain optimal growth conditions, including temperature and pH levels. Scientists can produce muscle tissue at larger scales using bioreactors. This capability significantly enhances the feasibility of lab-grown meat as an alternative to traditional production methods.

Types of Bioreactors

Different bioreactors serve various purposes and offer specific advantages for lab-grown meat production.

1. **Stirred-Tank Bioreactors**: These bioreactors use mechanical stirring to mix cell cultures. This design ensures uniform nutrient distribution and consistent oxygen levels. It promotes faster growth rates for cells, which is critical for scaling production.

2. **Perfusion Bioreactors**: Perfusion bioreactors continuously supply fresh media to cells while efficiently removing waste products. This setup allows for higher cell densities and yields. It enables producers to generate more lab-grown meat in smaller spaces.

3. **Fixed-Bed Bioreactors**: These bioreactors incorporate scaffolds for cell attachment. This design mimics muscle tissue’s natural structure. It helps create more complex textures in the final product, essential for consumer acceptance.

Innovations in Bioreactor Technology

Innovations in bioreactor technology drive the lab-grown meat industry forward. These advancements enhance efficiency, scalability, and product quality.

Automation and Control Systems

Modern bioreactors feature advanced automation and control systems. These systems monitor critical parameters like temperature and nutrient levels in real time. Automation reduces human error and increases consistency in production. Researchers can focus on optimizing cell cultures instead of manual monitoring. This change accelerates the research and development cycle.

Scalable Designs

Engineers design bioreactors with scalability in mind. As demand for lab-grown meat rises, manufacturers require larger production systems. Modular designs allow easy expansion of production capacity. This scalability is crucial for companies aiming to meet increasing consumer demands while managing production costs.

Alternative Cell Sources

Researchers explore various cell sources for lab-grown meat.

Conclusion

Bioreactors play a vital role in scaling lab-grown meat production. Innovations in technology enhance efficiency and product quality. Addressing challenges will further drive this promising industry forward.

Below are related products to the topic if you’re interested:

FAQ

What are bioreactors and how do they function in lab-grown meat production?

Bioreactors are vessels that facilitate biological reactions for lab-grown meat production. They house animal cells in controlled environments, supplying necessary nutrients and maintaining optimal growth conditions such as temperature and pH levels. This allows scientists to produce muscle tissue at larger scales, significantly enhancing the feasibility of lab-grown meat as an alternative to traditional meat production methods.

What types of bioreactors are commonly used in lab-grown meat production?

There are several types of bioreactors used in lab-grown meat production, each with specific advantages. Stirred-tank bioreactors utilize mechanical stirring to mix cell cultures for uniform nutrient distribution. Perfusion bioreactors continuously supply fresh media and remove waste, allowing for higher cell densities. Fixed-bed bioreactors use scaffolds to mimic natural muscle tissue structure, creating more complex textures in the final product.

What innovations are driving advancements in bioreactor technology?

Innovations in bioreactor technology include advanced automation and control systems that monitor critical parameters in real time, reducing human error and increasing production consistency. Additionally, scalable designs enable manufacturers to expand production capacity easily, addressing the rising demand for lab-grown meat. Researchers are also exploring alternative cell sources to improve the efficiency and quality of lab-grown meat

Post Comment