The Evolution of Cricket Bat Technology: From Willow to Modern Materials

The Evolution of Cricket Bat Technology: From Willow to Modern Materials

Cricket has a rich history that began in 16th-century England. Over the years, the game transformed significantly, especially regarding equipment. The cricket bat, an essential piece of gear, underwent remarkable changes. Initially, players used traditional willow bats made from Salix alba wood. Today, technology and materials have revolutionized bat design, enhancing performance and meeting players’ preferences. This blog explores the evolution of cricket bat technology, from simple wooden implements to sophisticated tools.

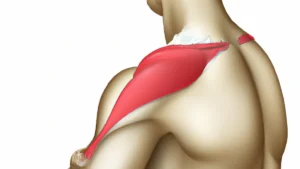

The Early Days: Willow Bats

Players originally crafted bats from English willow. This wood provides an ideal balance of strength, weight, and shock absorption. Willow’s fibrous structure absorbs ball impact, giving players a pleasant feel. The traditional bat shape, with its flat face and pronounced edges, maximizes batting efficiency. Early bats were heavy, requiring players to possess significant strength and technique.

The Rise of the Modern Bat

As cricket evolved, manufacturers experimented with materials and designs. By the late 20th century, the cricket industry experienced a surge in innovation to enhance bat performance. Companies began incorporating new technologies to improve power, durability, and precision. Larger sweet spots allowed players to hit the ball effectively, regardless of contact location on the bat.

The Importance of Weight Distribution

Weight distribution became crucial in modern bat design. Manufacturers learned to manipulate bat balance for different playing styles. Some players preferred lighter bats for quick shots, while others favored heavier bats for power. The concept of “pick-up” refers to how the bat feels in a player’s hands. A well-balanced bat feels lighter, enabling faster swings and better control. This focus on weight distribution led to various bat shapes and sizes, accommodating diverse player preferences.

Transitioning to Modern Materials

New materials significantly reshaped the cricket bat landscape. While willow remained popular, manufacturers began using fiberglass, carbon fiber, and Kevlar. These materials created bats that were stronger and lighter. Players now enjoy enhanced performance without sacrificing weight, allowing for better maneuverability and control.

The Impact of Technology on Bat Design

Advanced manufacturing techniques have transformed how cricket bats are produced. Computer-aided design (CAD) software enables precise measurements and intricate designs.

Conclusion

This post highlights the significant advancements in cricket bat technology over the years.

Below are related products to the topic if you’re interested:

FAQ

What materials were originally used to make cricket bats?

Players originally crafted bats from English willow, specifically from the Salix alba wood, which offered an ideal balance of strength, weight, and shock absorption.

How has modern technology impacted cricket bat design?

Modern technology has led to the incorporation of materials like fiberglass, carbon fiber, and Kevlar, resulting in bats that are stronger and lighter. Advanced manufacturing techniques, including computer-aided design (CAD), enable precise measurements and intricate designs, enhancing overall performance.

Why is weight distribution important in modern cricket bats?

Weight distribution is crucial as it affects how the bat feels in a player’s hands, influencing their swing speed and control. Manufacturers manipulate bat balance to cater to different playing styles, allowing players to choose between lighter bats for quick shots or heavier bats for power.

Post Comment